STAMPING PROCESSING TECHNOLOGY

Our stamping technology originates from the stamping of wristwatch movement parts and has a history of about 50 years.

Utilizing this precision press technology, we have expanded into various industries such as IT equipment parts and automobile parts.

We will protect this basic technology, evolve it further, and aim to open up new fields.

Elements of Komatsu Seiki's stamping technology

Technology 01

Accurate process design

Technology 02

Tool Design

Product Accuracy / Specification Feasibility, Ease of maintenance, Productivity

Technology 03

Tool Manufacturing

Advanced Manufacturing Accuracy and Repeatability

Technology 04

Stamping and Peripheral Machines, Measuring Equipment

Technology 05

Stamping Skills

Judgment, Teamwork, Cooperation

Technology 06

Maintenance skill, Maintenance Parts Supplying Capacity

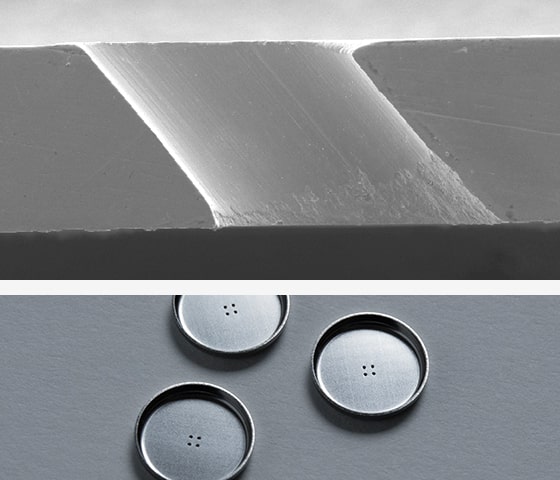

Angled Hole Stamping

Precise Holes Angled, Various Directions, Multiple Holes

We have developed angled hole stamping processing with our own technology, which overturns the common sense of vertical movement of stamping processing.

We have succeeded in drilling a diagonal hole with a minimum diameter of φ0.080 mm in a thin plate of 0.1 mm.

It is used for the tip nozzle of fuel injection equipment parts.

Compared to conventional electric discharge machining, tolerance management and quality have been greatly improved.

It has been 30 years since this angled hole stamping technology was developed in addition to the processing of wristwatch parts from the time of its founding.

Based on our abundant experience and knowledge of stamping, we will make proposals that meet the various needs of our customers.

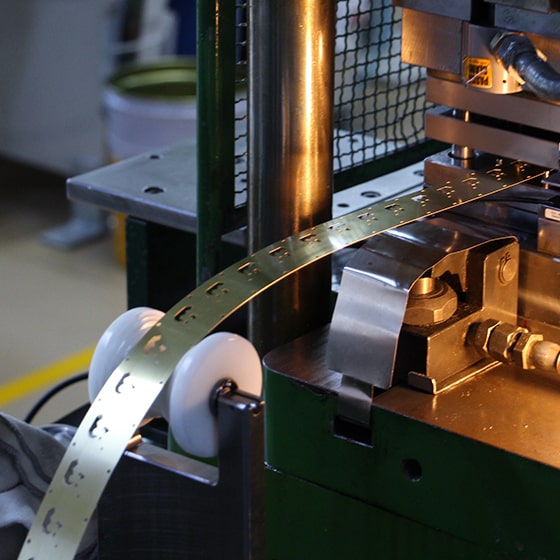

Precision stamping of fine and thin plates

Shearing, Piercing, Forming, Bending

Completed technologies such as high-quality shear, fine hole punching, drawing, and bending are essential conditions for wristwatch movement parts. We have cleared this condition, made it possible to guarantee the accuracy of each part with a dimensional tolerance of only a few μm, and have continued to maintain the quality of all processing in the mass production system.

Furthermore, in the processing of information equipment parts that require highly accurate positioning and stable vibration characteristics, we have realized press processing of thin springs with high accuracy and high balance with a width close to the plate thickness.

It was embodied by applying high-precision, fine-width spring stamping technology, which has a proven track record in stamping wristwatch parts, and received high praise.

Integrated Processing of Tool Design-Tool Manufacturing-Serial Production

Stamping technology, which began with wristwatch parts, has made the impossible possible in a variety of products. We have built a complete integrated processing system of mold design-mold production-mass production processing, and in mold production, all except standard parts are manufactured in-house without relying on other companies.

Manufacturable material specifications

- Work material

- Stainless steel, copper alloy, special alloy, plastic film, etc.

- Thickness

- from t = 0.03mm

CONTACT

Inquiries by Phone or Fax

Please feel free to contact us for any inquiries regarding technology or products.

- +81-(0)266-52-6100

- +81-(0)266-58-1796